Tell me more about how the valve lathe controls the operation.

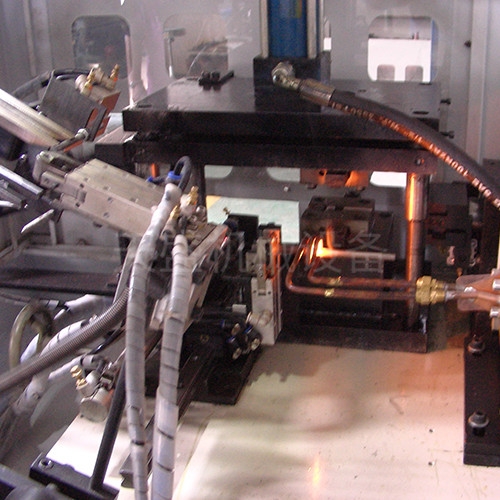

How to choose the running route of each of the four tool holders of the control valve lathe? On the right side of the tool post operation sequence, we can see that there are four knob switches. Each knob switch can directly control the running path of each tool holder. The selected gear position of the tool holder I is a punching action. The shape of the tool holder position is: the round point is the starting position of the tool holder, the solid line indicates the infeed path, and the broken line indicates the retracting path; the tool holder II The gear position is the tapping action; the tool holder is also the action of punching; the tool holder IV is the action of slotting or cutting. If the tool holder does not need to be able to switch the switch to the O position, the tool holder will no longer move during automatic operation.

Many customers will ask: Where is the size and the speed of the knife? Both the machining size and the cutting speed are not controlled on the panel. Each of the radial and axial guides has two knobs on the back of the rail to control the position of each rail in and out. The tool holder speed is controlled by the damper on one side of the guide rail. The damper cylinder does not work until the knife hits the part. The tool quickly approaches the part. When the tool is about to hit the part, the damper function can slow down the tool holder. The feed speed, so that the tool can be machined stably and evenly at the same time, the speed of the damping cylinder can be adjusted steplessly.

The above is the role of the main gear in the automatic operation, then we look at how the program-controlled valve lathe alone controls each moving part of the machine.

We will switch the operation mode of the rotary switch to the “debug” position, and then press the green “run” button. The white button area on the hand in the above figure can control each moving part separately. These buttons play a very important role in the replacement of the machined parts, and the valve lathe makes it easy to adjust the tool.

The address of this article:http://www.hfdzr.com/en/news/380.html

Key word:氣門(mén)磨床,氣門(mén)車(chē)床,氣門(mén)設(shè)備

The next one:How to make the industry of valve lathe processing rise

Recently browse:

Related products:

Related news:

- Main features of welding of rod end drilling machine for valve equipment

- So how should the principle and function of the valve device be understood?

- What adjusts the clearance of the valve lathe?

- What are the advantages of an automatic valve lathe as a guide feed thrust?

- Tiansheng Xiaobian explains to you the classification of engine variable valve equipment intake

- Talk about the special equipment for the valve starting and starting the valve

- Safety precautions for using valve lathes

- The steps and methods of valve machine fault handling are nothing more than

- Learn about the independent entry and exit of the valve lathe system

- How to make the industry of valve lathe processing rise